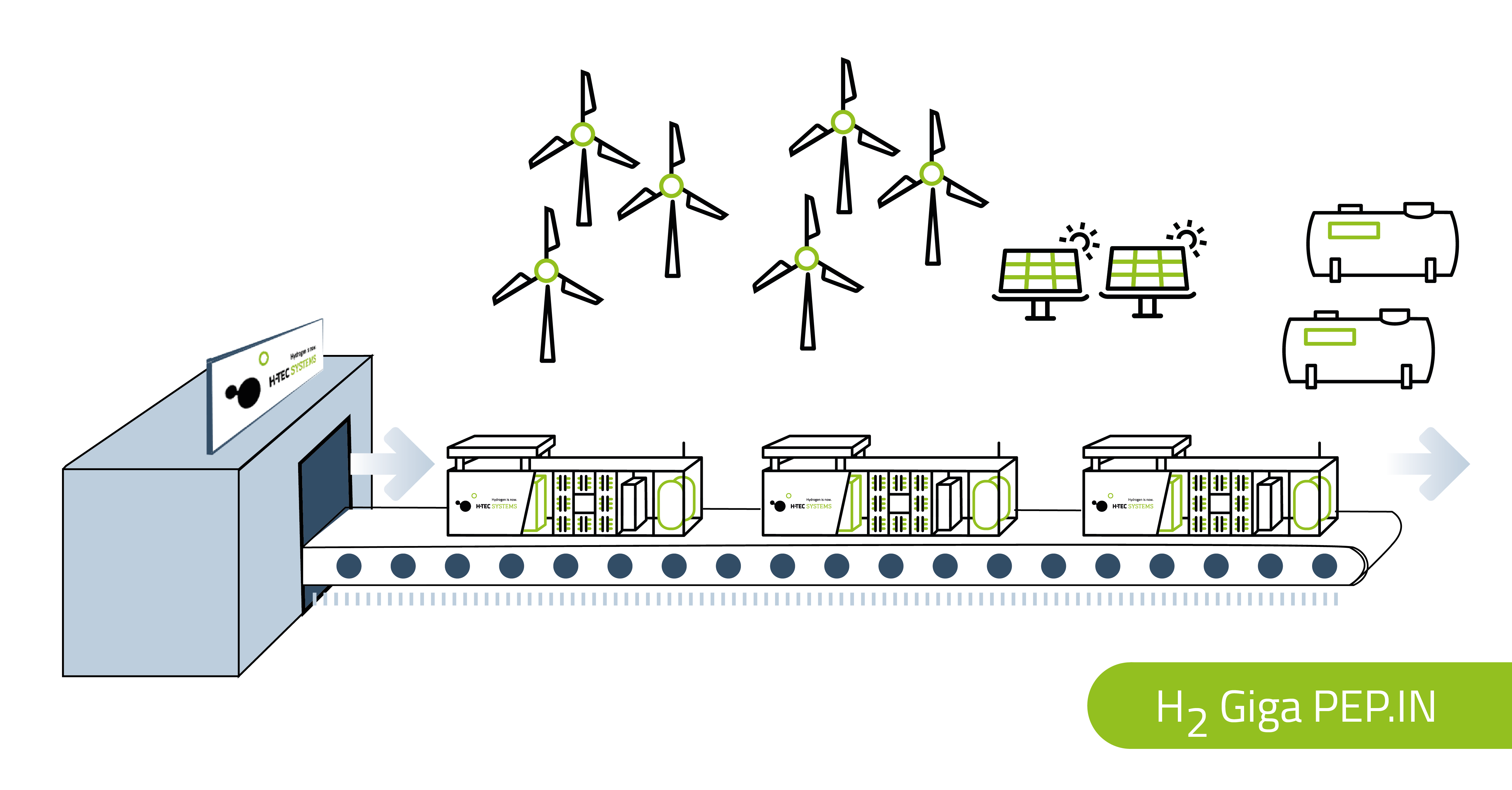

Green hydrogen is a key building block for the renewable energy transition in all sectors: For mobility, industry, and heating, the environmentally friendly energy carrier has become the focus of attention for the German government and the EU Commission. H-TEC SYSTEMS, a technology leader in in the manufacturing of PEM Electrolysers for the production of green hydrogen, leads the way at Germany’s largest hydrogen mobility project eFarm.

Dynamic and cost efficient operation

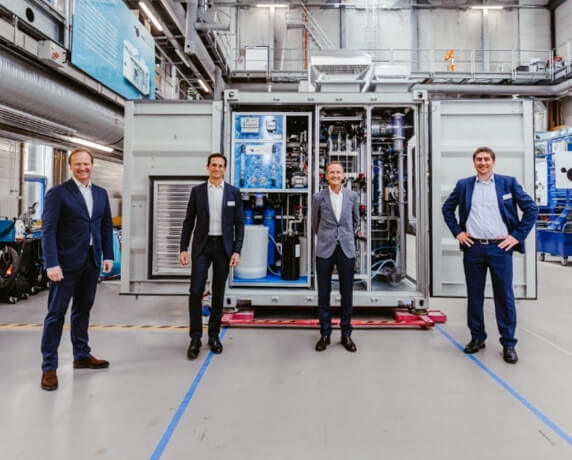

The innovative production of green hydrogen from wind energy in GP JOULE’s project eFarm brought Germany’s Federal Transportation Minister Andreas Scheuer and Schleswig-Holstein’s State Energy Minister Jan Philipp Albrecht to the inauguration in Bosbüll, North Fresia. The ME 100/350 electrolyser used in the eFarm pilot project is the result of 20 years of research and development by the hydrogen experts at H-TEC SYSTEMS – Made in Germany.

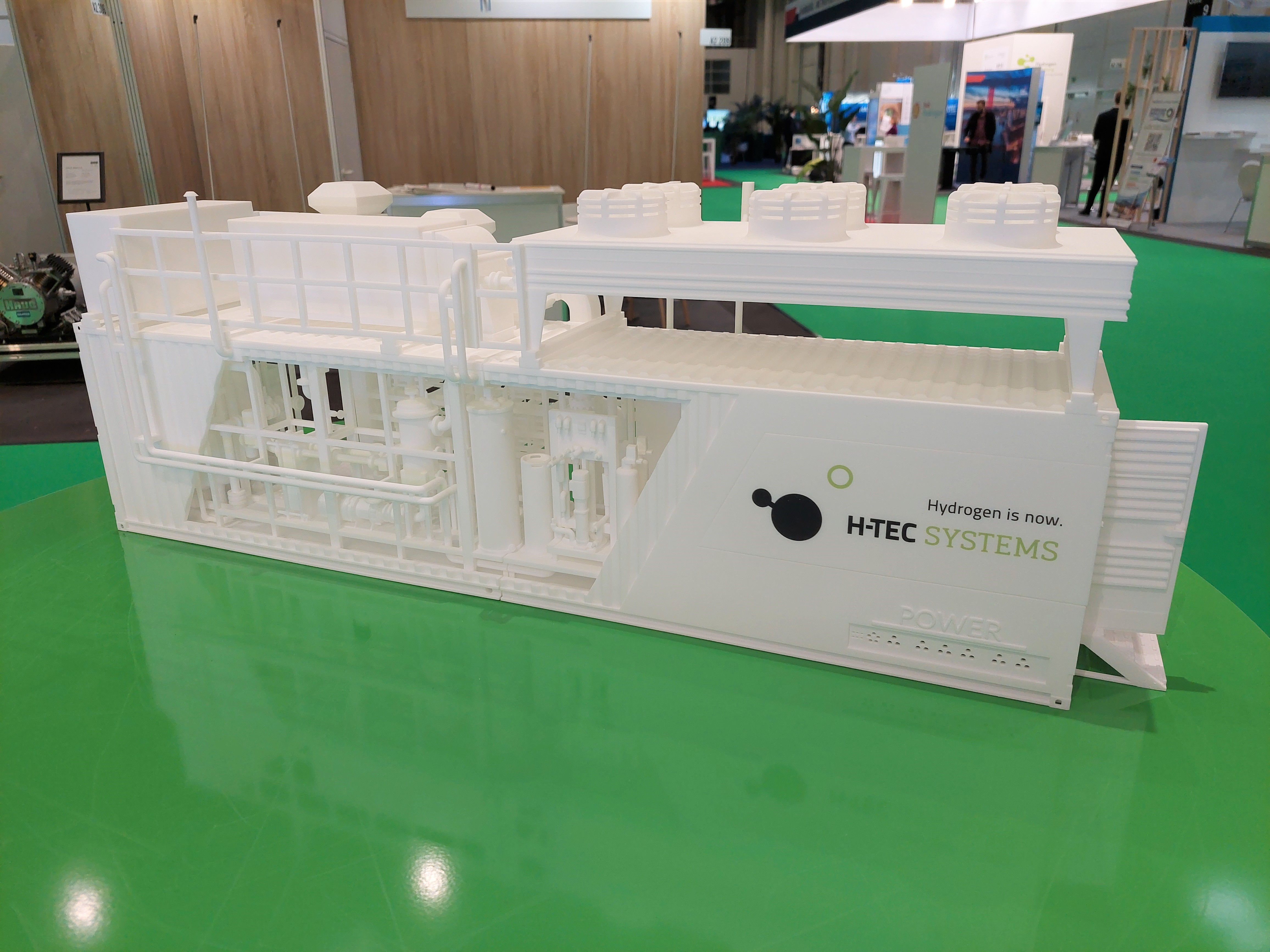

”The highly flexible H-TEC SYSTEMS electrolysers are perfect for the dynamic availability of renewable energy,” says Ove Peterson, CEO of the GP JOULE group in Reußenköge and initiator of the project eFarm. ”The container solution of the H-TEC SYSTEMS electrolysers was just as convincing as the good price-performance ratio, which leads to minimal hydrogen production costs.”

High added value with 95 % efficiency

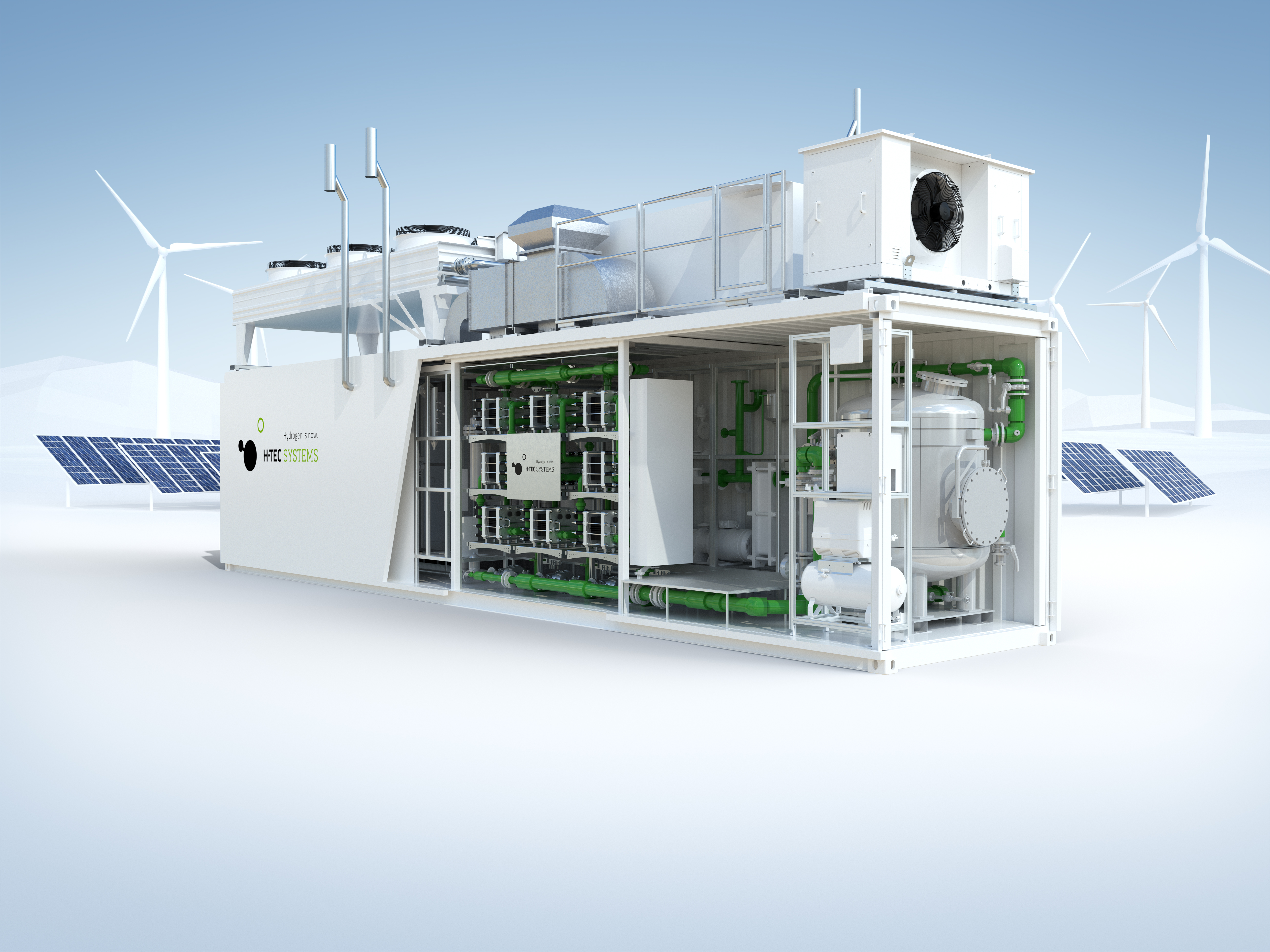

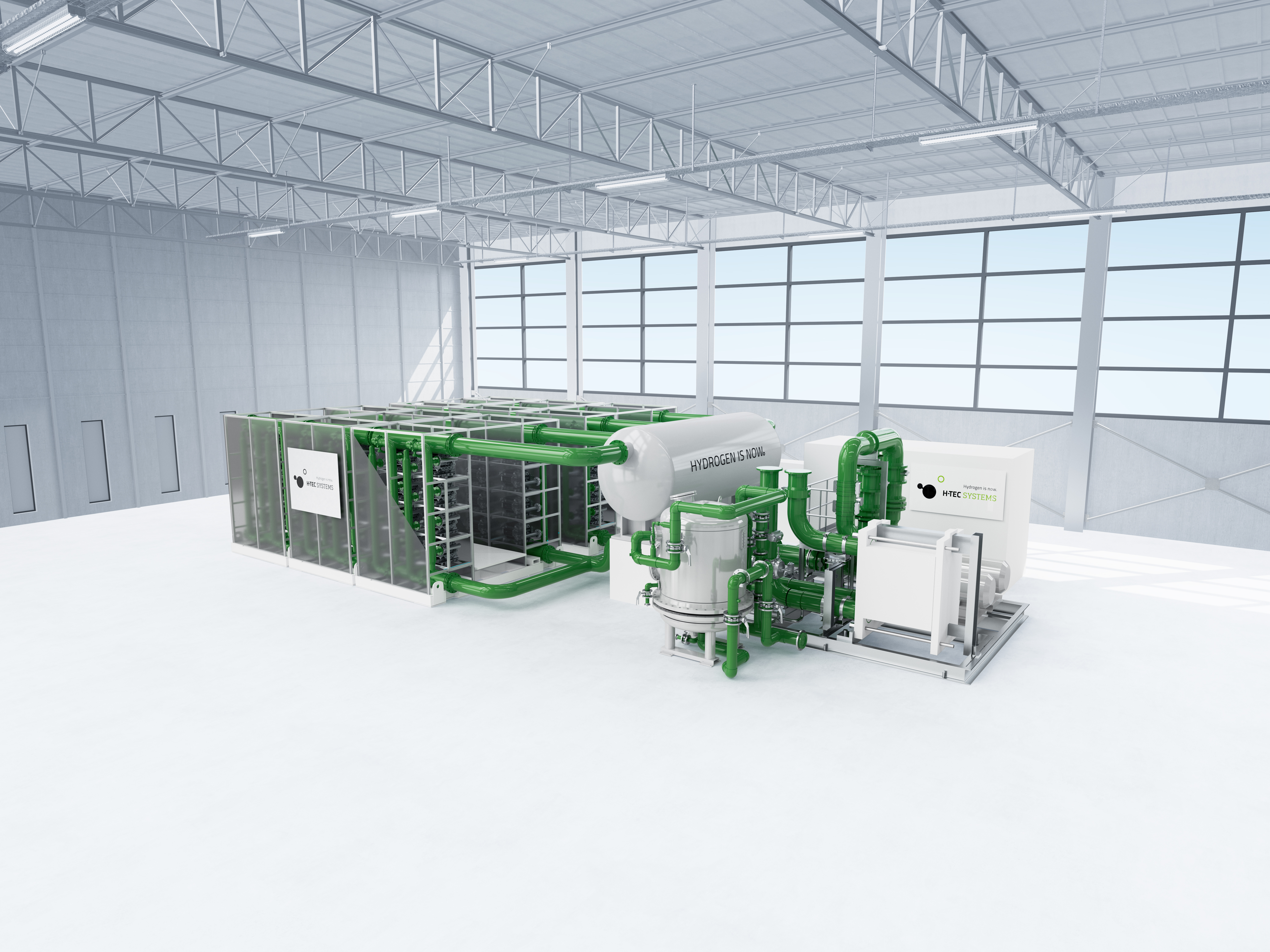

The joint project eFarm will use a total of five electrolysers, each of which can produce up to 100 kg of hydrogen per day from drinking water and electricity, with a nominal load of 225 kW each. The mobility project eFarm will provide hydrogen for private and public transportation by means of two filling stations.

”Our modular and flexibly deployable electrolysers are ideal to contribute to the climate neutral mobility of the future with green hydrogen,” explains Heinrich Gärtner, CEO of H-TEC SYSTEMS, and adds: ”The high quality hydrogen produced is suitable for operating fuel cell vehicles without further refinement.”

‘Think integrated‘ is the motto of the Augsburg company, and this is also how they create the possibility for using the waste heat from the electrolysis process. At eFarm it flows into the regional heat supply for industry and provate homes. This enables H-TEC SYSTEMS electrolysers to achieve an efficiency of up to 95 %.

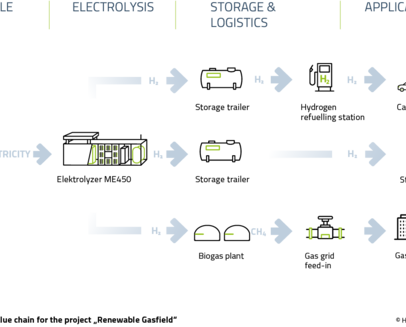

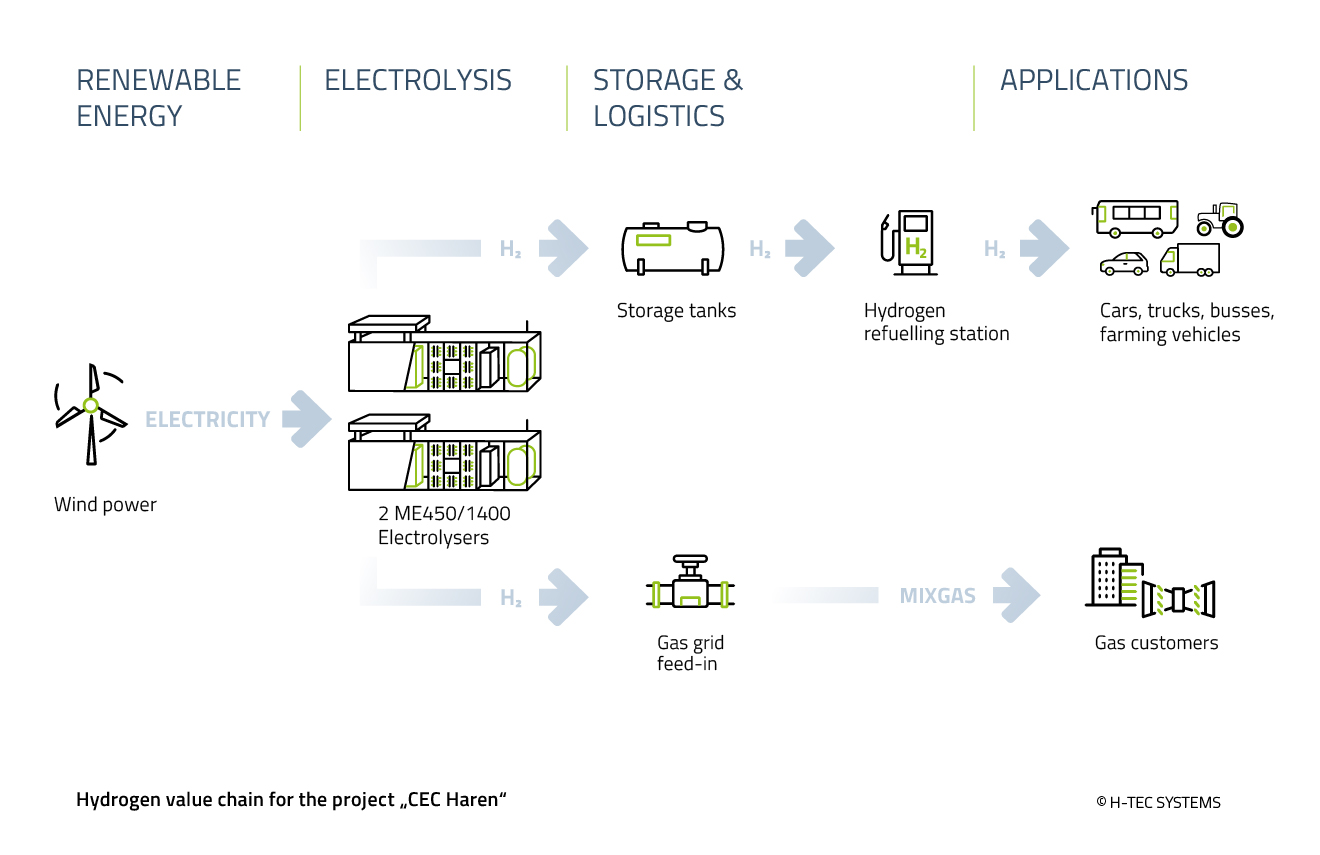

Electrolysers for diverse applications

”Green hydrogen can be produced by anyone who has access to renewable energy and about 14 square meters [150 sq ft] of space for the electrolyser,” says Heinrich Gärtner. ”For operators of wind and solar plants whose German Renewable Energy Act funding is expiring, sector integration by means of hydrogen is a good way for them to continue using their plants profitably.”

H-TEC SYSTEMS supplies the high-tech electrolysers as a turnkey solution integrated into 20 or 40 foot containers. These compact solutions can be implemented anywhere—directly at wind and solar parks, at filling stations, or in industrial plants.

Image: © H-TEC SYSTEMS

![[Translate to English:]](/fileadmin/user_upload/QMA_HTecSystems_02.jpg)

![[Translate to English:]](/fileadmin/user_upload/H-TEC_SYSTEMS_Bosbuell_7-min.jpg)

![[Translate to English:]](/fileadmin/user_upload/csm_220622_25_Jahre_H-TEC_994e75090f.png)