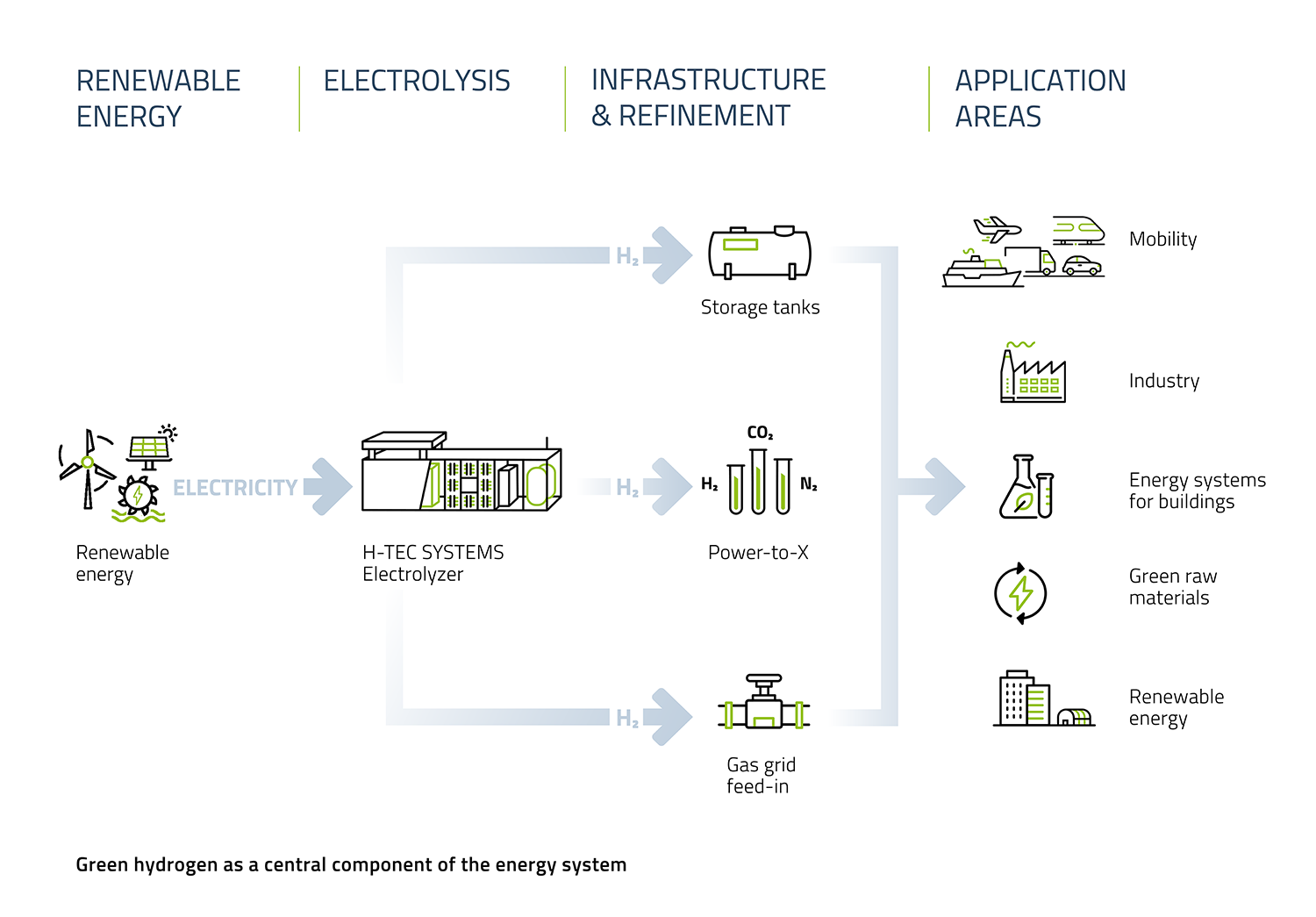

Producing green hydrogen from renewable energy

Pure water, renewable energy, and H-TEC SYSTEMS: That's all it takes to produce green hydrogen. To meet these challenges, we have been continuously optimizing PEM electrolysis and increasing the productivity of our plants. The result is a technological advance that will enable the decarbonization of a wide range of industries - not in the future, but today.

Hydrogen production and storage on-site is a decisive step toward energy self-sufficiency. When produced with 100 % renewable electricity, green hydrogen makes an important contribution to reducing CO2 emissions. Germany's aim is to reduce emissions by 55 % by 2030 and 95 % by 2050. This goal cannot be achieved with "blue" or "gray" hydrogen, which are produced using fossil fuels.

The PEM electrolysis technology from H-TEC SYSTEMS is specifically designed to produce green hydrogen, enabling sector integration. This creates synergies. And plenty of new opportunities.

CO₂-neutral mobility

Mobility leaves a footprint - at least up to now. Hydrogen from our PEM electrolysis can be used directly for fuel cells and is therefore emission-free and climate-friendly. That makes traffic cleaner and quieter. Power-to-X processes make it possible to generate fuels for aircraft or ships.

Raw material for industrial goods

Mixing carbon dioxide (CO2) and hydrogen (H2) produces a high-quality syngas. This is a pioneering process for capturing CO2 emissions and using them to produce the chemical building blocks for chemicals, polymers, or synthetic fuels. Even the production of ammonia (NH3), the main ingredient for mineral fertilizers, is possible with climate-friendly green hydrogen.

Decarbonization of industrial processes

The production and processing of raw materials and goods requires large amounts of energy. Hydrogen can improve the CO2 balance of these processes, e.g. heating of kilns in glass, cement, or steel production. Hydrogen can be fed into the natural gas network at rates of up to 10 % and more, providing a long-term energy storage solution.

Decarbonization of domestic energy systems

Electrolysis not only produces hydrogen, but also approx. 50°C heat as a by-product. This is valuable energy that can be fed into the district heating network or used directly to heat residential and commercial premises. Fuel cell heating systems also benefit from the principle of cogeneration.

The advantages of PEM electrolysis

at a glance

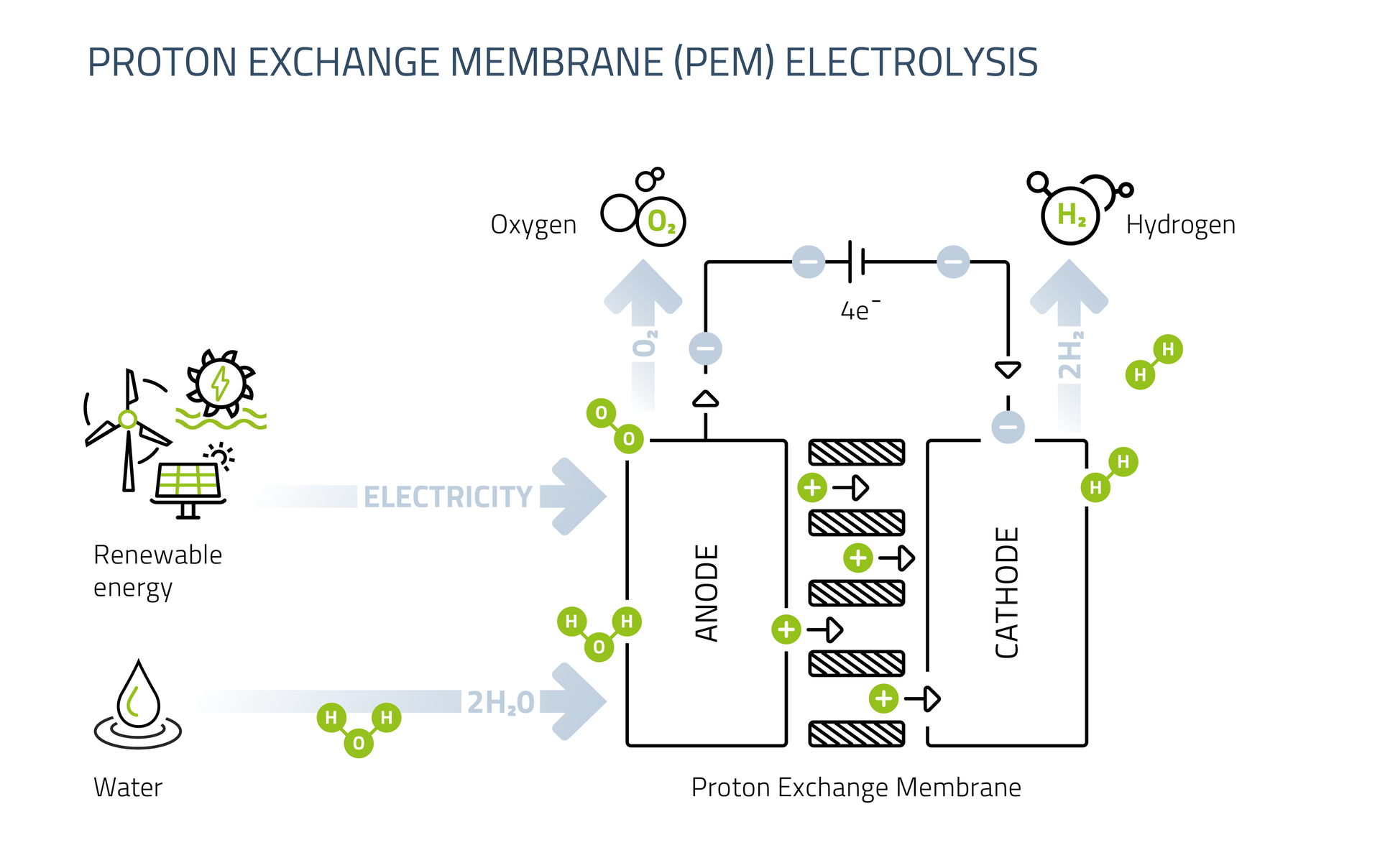

PEM stands for "Proton Exchange Membrane", which in turn stands for a whole host of advantages:

- PEM electrolysis is the preferred technology for green hydrogen production, by splitting water with electricity

- Can be operated in the dynamic partial-load range, i.e., compensating for the load fluctuations of renewable energy

- PEM produces high-purity hydrogen that can be used directly for refueling

- Does not require aggressive chemicals and does not use a liquid electrolyte

- Tried-and-tested technology, now ready for use on an industrial scale with H-TEC SYSTEMS