The energy transition process is not possible without hydrogen, explain experts from technology, business and politics. According to the latest studies, many members of the public are also of the opinion that hydrogen will play a decisive role in mobility and the economy in the future. The European Green Deal and the goal of further reducing greenhouse gases will ensure that the legal requirements for emission limits for vehicles will probably continue to become stricter especially in the transport sector. This increases the pressure on vehicle manufacturers to introduce alternative drive systems more widely. Pressure on the industry is also increasing. Does hydrogen have a perspective in industrial applications? And is it a building block for the mobility of the future? In spite of positive expert assessments, some persistent myths about the energy balance and market maturity of hydrogen continue to circulate in the media and the public in general. Hydrogen expert Tino Krüger, Senior Product Manager at H-TEC SYSTEMS, refutes five common assertions.

Myth 1: Hydrogen is not so environmentally friendly

Hydrogen is considered to be a climate-neutral and efficient energy carrier. During its combustion, only water vapor is produced and no environmentally-harmful substances are released. However, if the energy required for hydrogen production comes from fossil fuels, then this argument only applies to a limited extent. This is known as "grey" hydrogen. Green hydrogen is produced through the electrolysis of water, using only electricity from renewable energies. The production of "green" hydrogen by means of PEM electrolysis is therefore completely CO2-free. In addition, the green hydrogen is suitable as a storage medium for renewable energies and can be used, for example, to compensate for fluctuations in the power network as it can be conveniently stored in the natural gas network or in tanks over a long period of time.

Myth 2: Hydrogen production is too expensive

As the production of hydrogen meanwhile is now very mature and technologically manageable, production can be ramped up quickly in case of corresponding demand. When it comes to technologies and processes, prices always fall significantly as soon as production capacities increase. The falling prices for renewable power also lower the costs of producing green hydrogen because up to 75 percent of the costs incurred for PEM electrolysis can be attributed to the demand in electricity. In the best case, however, investment and maintenance costs only represent around 25 percent of cost requirements. Depending on the conditions, these cost distributions can fluctuate. Hence, if the price of electricity falls, the costs for producing green hydrogen from PEM electrolysis also drop. Especially in view of the increased gas prices, green hydrogen is becoming increasingly more lucrative. According to calculations by analysts at Bloomberg New Energy Finance (BNEF), green hydrogen is already cheaper than fossil hydrogen from natural gas in parts of Europe, the Middle East and Africa.

The Hydrogen Council, an association of over 90 international companies, expects the costs of many hydrogen applications to be halved during the next ten years. As a result, this will open up competitiveness for even more areas of application.

Myth 3: Efficiency losses in hydrogen production are too high

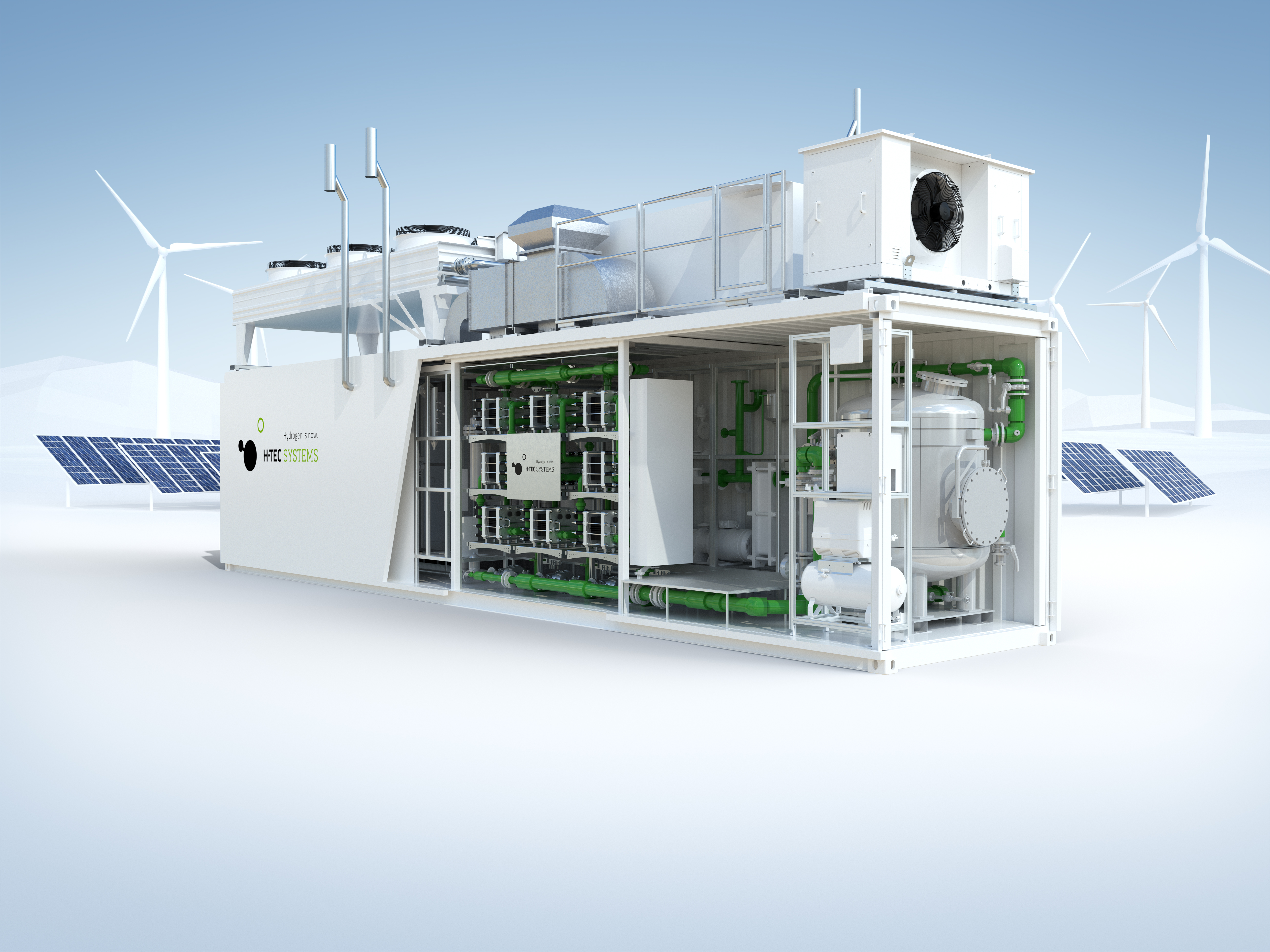

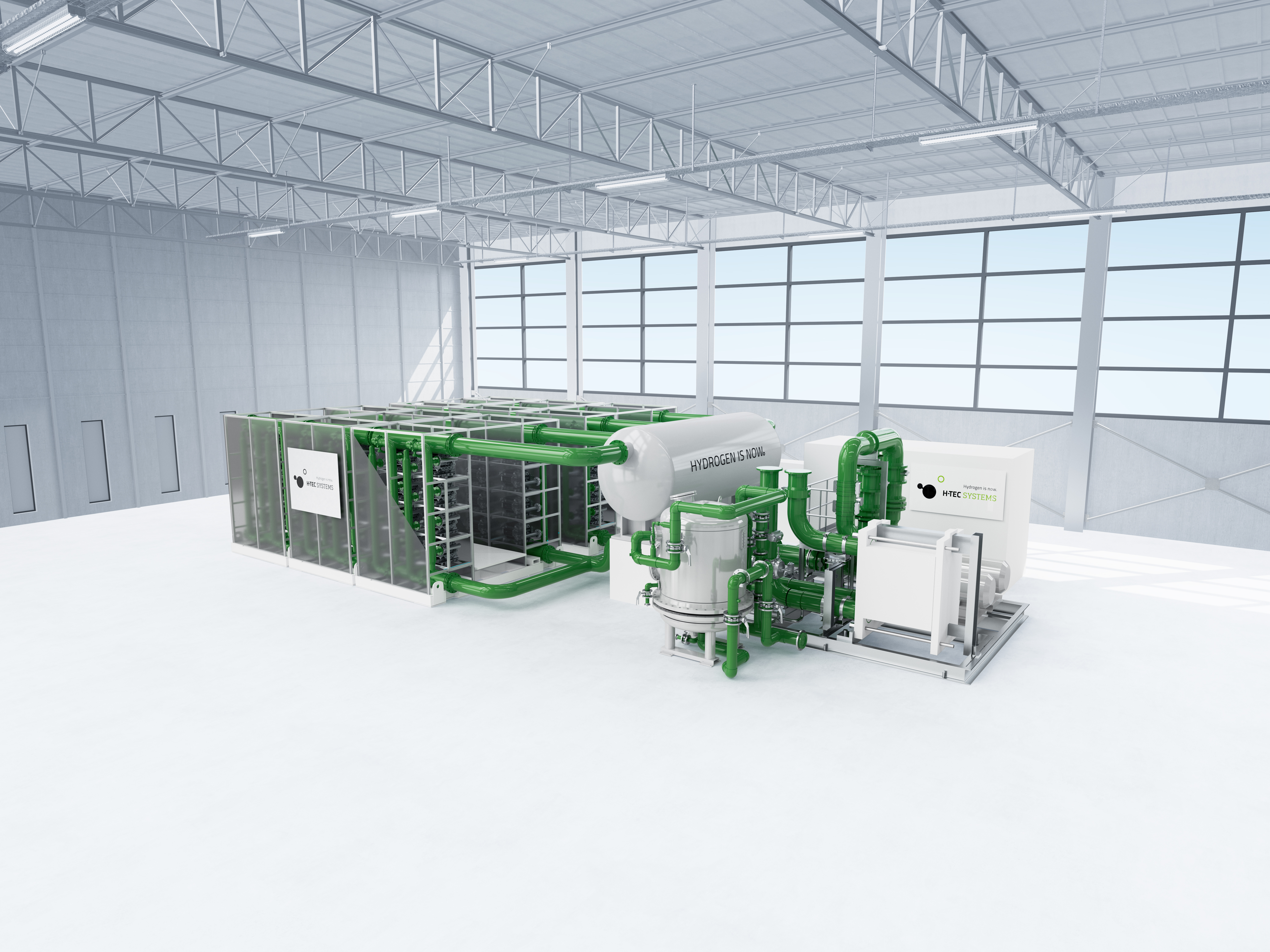

The rule of thumb is that up to 25 percent of the energy used to produce hydrogen is lost in the form of heat. Depending on the process, this percentage is already lower today. If this heat is captured and fed into a heating network, the "loss of efficiency" can be used as an energy source for other applications. The sustainably generated energy can be fed into the district heating network or used directly to heat residential and business premises. The H-TEC SYSTEMS ME450 electrolyzer, for example, offers especially high efficiency. With a total electrolysis performance of 1 megawatt, it achieves a system efficiency of 75 percent, and even up to 90 percent when using heat.

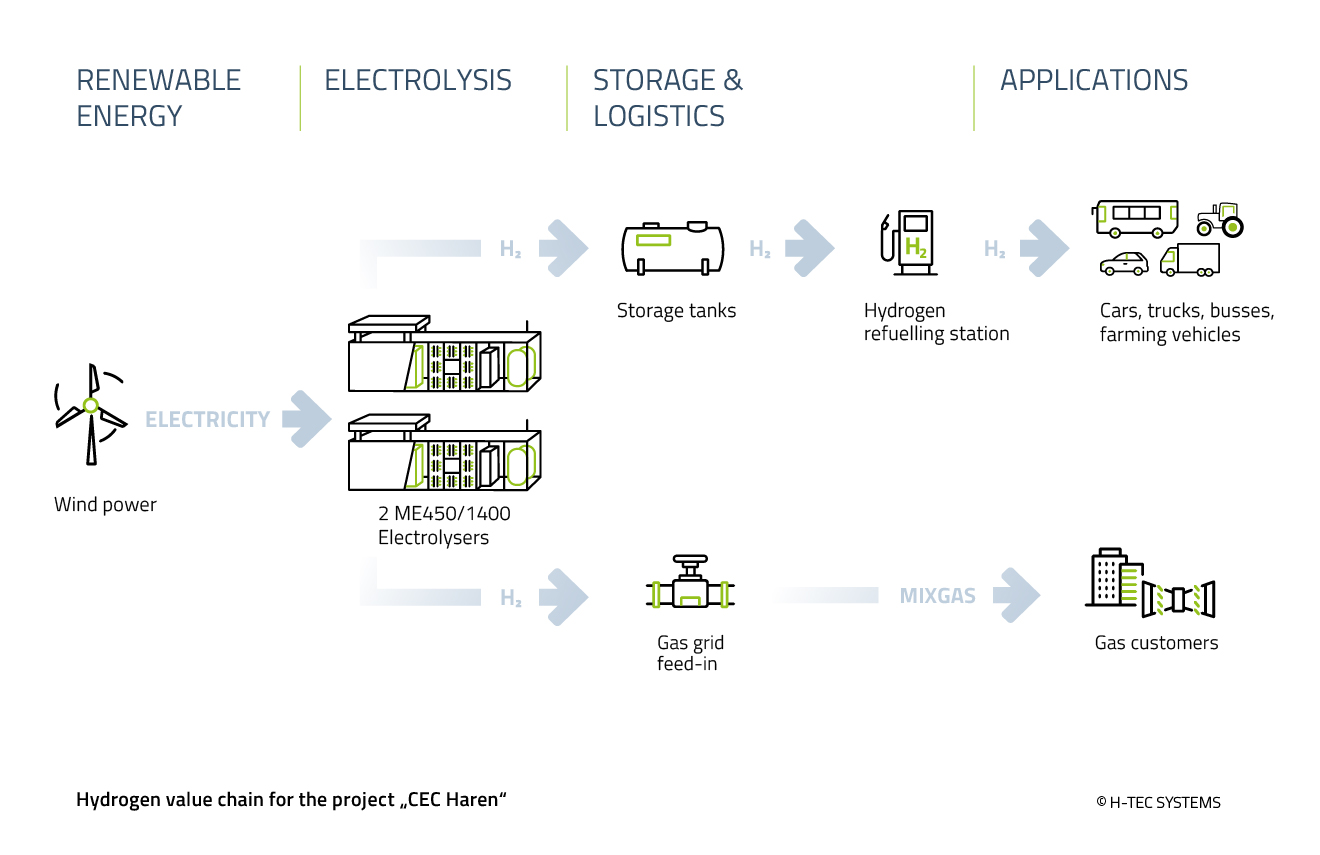

Hydrogen production thus provides the basis for a so-called sector coupling. By networking the three sectors of the energy industry - electricity, heating supply and mobility - projects become significantly more sustainable and economical.

Myth 4: Hydrogen is not suitable for mobility

Hydrogen is frequently presented as a competitor to electric vehicles with battery storage. In each case, both approaches are suitable for different areas of application. Electric cars with batteries are becoming more and more economical. However, the heavier the vehicle is, the more impractical the required batteries would become as they would weigh several tons and still have a short range and long recharging times. According to the Federal Environmental Agency, the larger and heavier a vehicle is and the further it has to drive, the more sensible it is to use hydrogen. This primarily includes shipping but also the propulsion of aircraft or trains.

According to recent studies, commercial vehicles emit around a third of the greenhouse gases in the domestic German transport sector. The larger part of these emissions can be traced back to heavy commercial vehicles in the 26 to 40 t range involved in long-distance freight transport. Therefore, their drive technology has a particularly high potential to make an effective contribution to climate protection. Airplanes, ships, commercial vehicles, heavy road traffic, local public transport or other processes in the logistics sector are areas of application that, according to the Chamber of Commerce and Industry, can benefit from using hydrogen and for which there are already successful projects in practice. Modern hydrogen buses have a range of 350 km and, with 8 to 12 kg H2/100 km, have significantly less consumption than their diesel counterparts. Heavy commercial vehicles with fuel cell drive systems can reach ranges of up to 1,000 km and consume around 8 kg of H2/100 km. Fuel cells are also already in use in local rail passenger transport. Pilot projects have achieved a range of 1,000 km with a consumption of 18 to 28 kg H2/100 km and are now being entered into regular operation.

Myth 5: Hydrogen applications are still a dream of the future

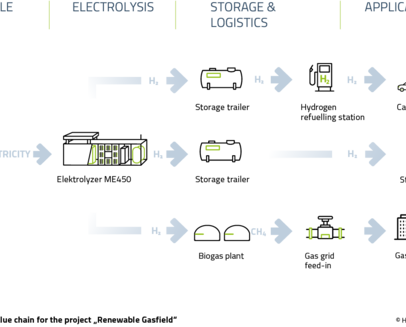

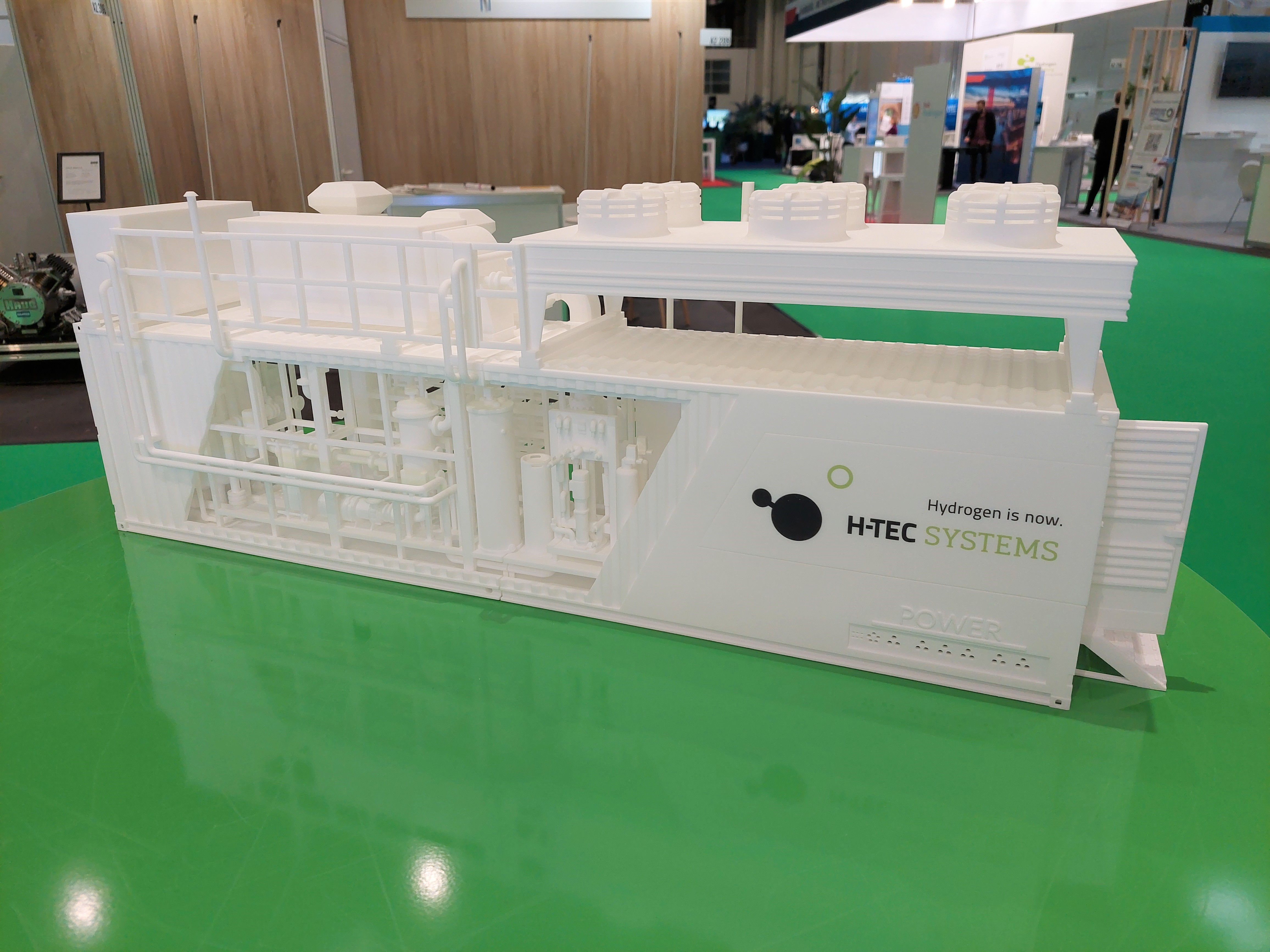

At industry events such as the Hanover Fair or HUSUM Wind, visitors have been able to see for themselves for several years now that even the newer green hydrogen is no longer just a vision of the future. Practical projects showed, among other things, how successful sector coupling can be when implemented through the interaction of community wind and solar parks together with the production of green hydrogen. In the process, hydrogen is already being used cost-effectively for green mobility, heating supply as well as being fed into regional energy networks. Already today, 10 percent and more can be fed into the natural gas network and stored.

Green hydrogen plays a special role in the decarbonization of industrial processes. There are already practical examples of how it has been used successfully – for example, for heating kilns in glass, cement or steel production. According to the Chamber of Commerce and Industry, the steel industry alone is responsible for eight percent of CO2 emissions in Germany. According to the association’s latest forecast, around 80 percent of emissions could be avoided by switching to hydrogen and natural gas.

Other options for using hydrogen as a raw material for producing industrial products are already being tested. By mixing hydrogen (H2) and carbon dioxide (CO2), this results in a high-quality synthesis gas. Through this forward-looking process, which is being used very successfully in Iceland, for example, CO2 emissions can be captured. Chemical building blocks for chemicals, polymers or synthetic fuels can be produced from the synthesis gas. Even ammonia (NH3), the main component of mineral fertilizers, can be produced with climate-friendly hydrogen production.

According to a study carried out by the European Patent Office (EPA) and the International Energy Agency (IEA), Germany is currently the leader in hydrogen patents in Europe and ranks second worldwide after Japan. Furthermore, Europe has a lead in production capacities for electrolyzers whereby Germany is represented through two world-wide leading regional clusters (Munich and Ruhr areas).

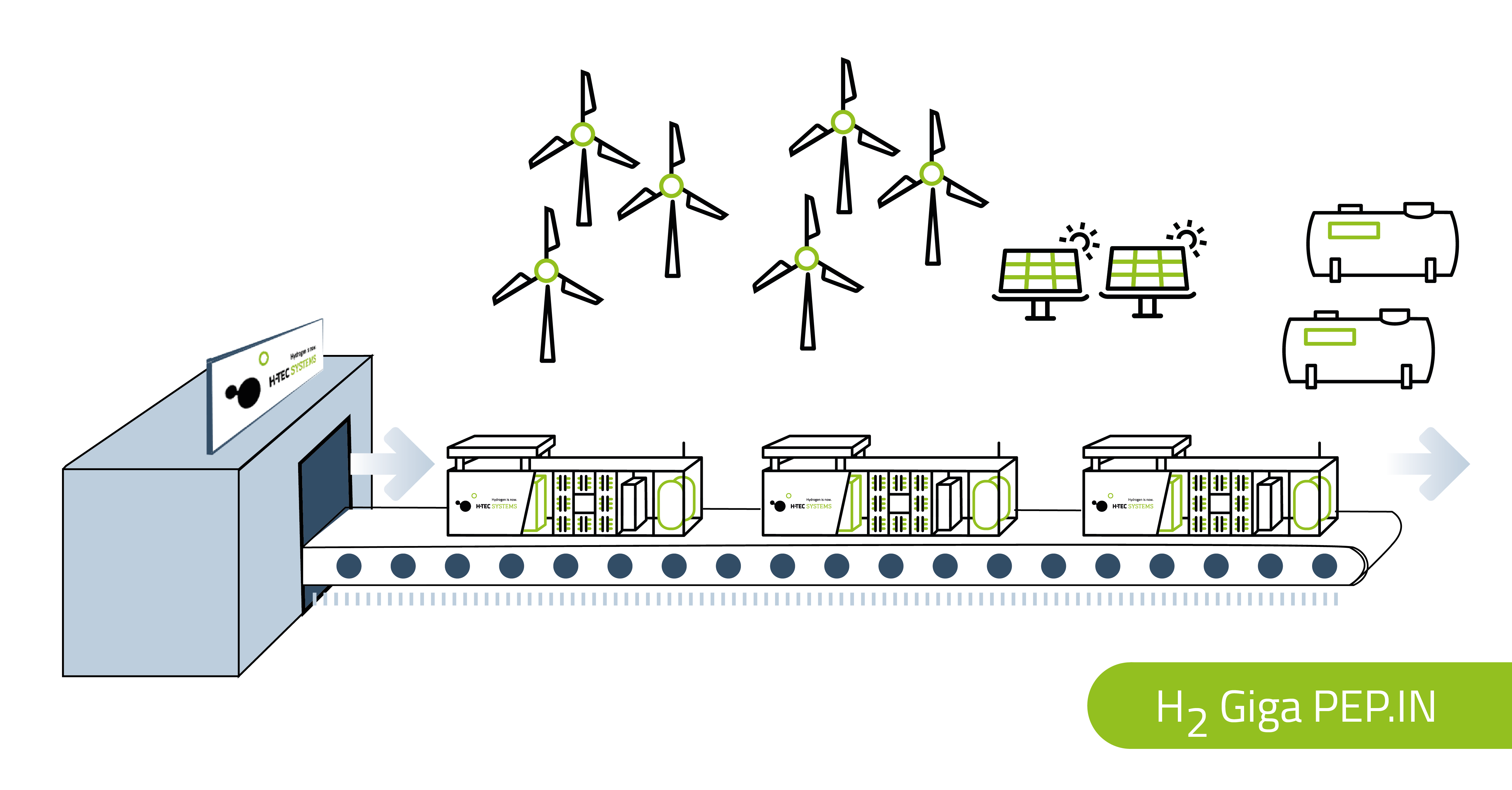

"Our PEM electrolysis technology is specially designed for the production of green hydrogen and thus for sector coupling. We can therefore confirm the increasing demand from industry and municipalities first-hand,” explains Tino Krüger, Senior Product Manager at H-TEC SYSTEMS. "We are continuously expanding our production capacities and will complete the construction of a gigafactory for the serial production of PEM stacks by the end of 2023. Our electrolyzers are already being used in projects throughout Europe and which show how economically and sustainably green hydrogen can be used - whether it is a hydrogen infrastructure project in Schleswig-Holstein, an emission-free microgrid in Sweden or the gas grid feed-in for less CO₂ emissions in northern Germany.”

Further information on technologies and applications with green hydrogen is also available at https://www.h-tec.com/en/hydrogen/

![[Translate to English:]](/fileadmin/_processed_/3/6/csm_H-TEC_SYSTEMS_Bosbuell_7-min_3b97b66c77.jpg)

![[Translate to English:]](/fileadmin/_processed_/b/2/csm_H-TEC_Tino_Krueger_fe66eb9852.jpg)

![[Translate to English:]](/fileadmin/user_upload/QMA_HTecSystems_02.jpg)

![[Translate to English:]](/fileadmin/user_upload/csm_220622_25_Jahre_H-TEC_994e75090f.png)